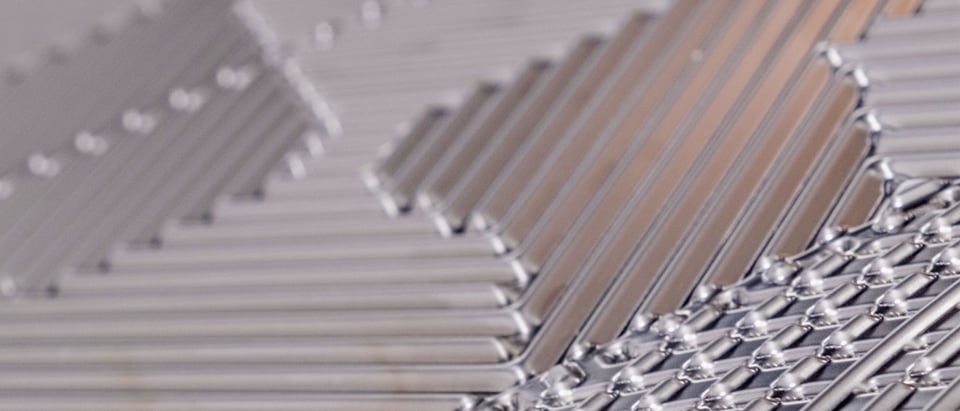

Plates customized to your needs

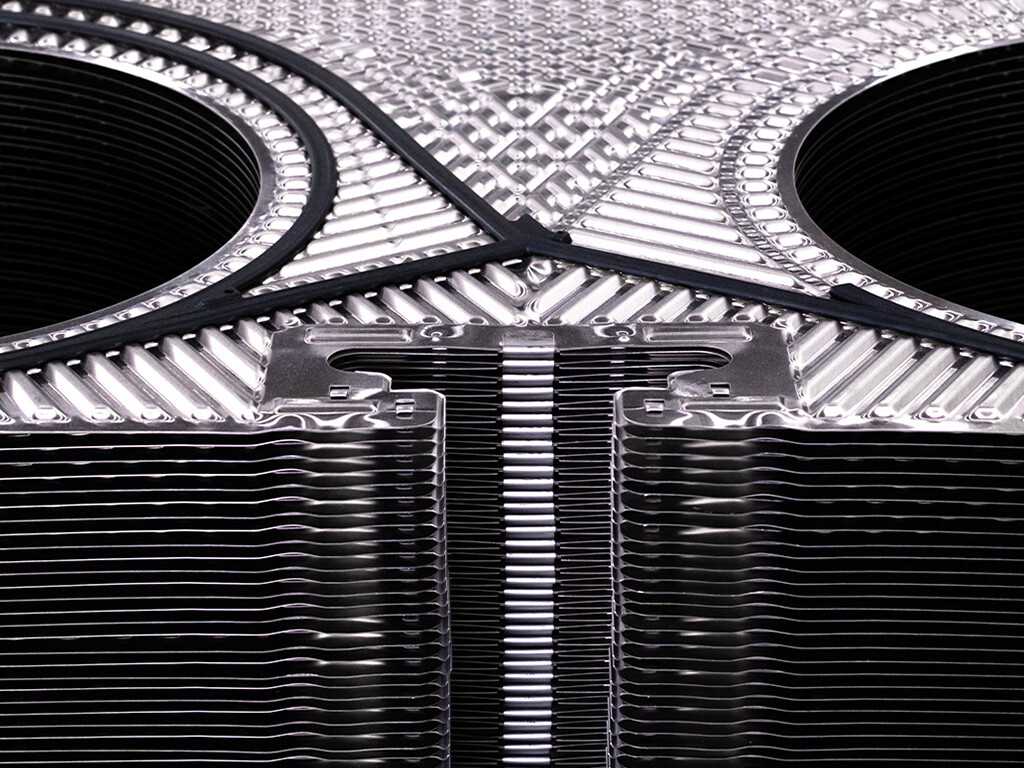

Tranter offers both individual plate assemblies (complete with pre-attached gaskets) and full plate packs tailored for your specific heat exchanger needs, catering to Tranter as well as other brands in the market.

Heat exchanger parts and accessories

Spare Parts and Accessories

Tranter offers both individual plate assemblies (complete with pre-attached gaskets) and full plate packs tailored for your specific heat exchanger needs, catering to Tranter as well as other brands in the market.

Standard gaskets are available in NBR or EPDM material. NBR gaskets have a maximum temperature of 140°C (284°F) while EPDM gaskets can withstand up to 170°C (338°F). Explore additional material options like FKM (Viton), HNBR, EPDM-RC, and more.

Choose from a variety of standard and custom sizes for our Clean-In-Place (CIP) systems.

Drip pans prevent water and other liquids from draining onto the floor when dismantling the heat exchanger.

Insulated shrouds help prevent condensation from forming on the outside of cold plates. Standard shrouds provide personnel with protection from hot and sharp surfaces and help to protect the plate pack from impacts and bumps.

A strainer protects the plate pack from large particles that would otherwise foul and clog the channels. The length is adapted to the number of plates.

Specially designed covers shield personnel from sharp tie bolt threads, boosting safety measures around the unit.

INNOVATION AND PRODUCT DEVELOPMENT

Leveraging technology and innovation to deliver superior service experiences.

Resource center

Parts and services

When it comes to inspection and plate removal, it's crucial to pay attention to every detail. By following the necessary steps and taking the time to inspect and remove plates properly, we can ensure that your project is completed successfully. Learn more by listening to Dave Lusignolo, Director, Aftermarket Sales - North America

Parts and services

Chemical cleaning and rinse are essential steps in maintaining the performance of your heat exchanger. Whether it's removing liquids, or ensuring the longevity of machinery, chemical cleaning and rinse play a crucial role in the service process.

resourse center

Are you considering service for your heat exchanger?