Communication

Gain immediate, expert advice on streamlining projects to drastically cut down on administration time. Tranter combines small-company agility and customer focus, ensuring personalized attention to every customer's needs.

Improving efficiency and energy savings

Digitalization, electrification and the energy transition drive an increased demand of semiconductors and microelectronics for solar cells, LED lighting and microchips and printed circuit boards for computers and control systems. In semiconductor manufacturing, efficient and reliable heat exchangers are crucial to control the temperature and humidity in the cleanroom, water treatment of ultrapure water and process water, cooling the coolant/cutting slurry in the wafer preparation and heating and cooling of the acids and chemicals needed for the etching process.

Semiconductors

Gain immediate, expert advice on streamlining projects to drastically cut down on administration time. Tranter combines small-company agility and customer focus, ensuring personalized attention to every customer's needs.

Minimize your project expenses effectively by implementing strategic cost-saving measures. Adopting efficient planning, and ongoing cost analysis can dramatically reduce unnecessary expenditures.

Our team of experts is committed to ensuring your operations run smoothly and efficiently, providing energy assistance on a global scale to improve productivity and promote energy conservation.

Semiconductors

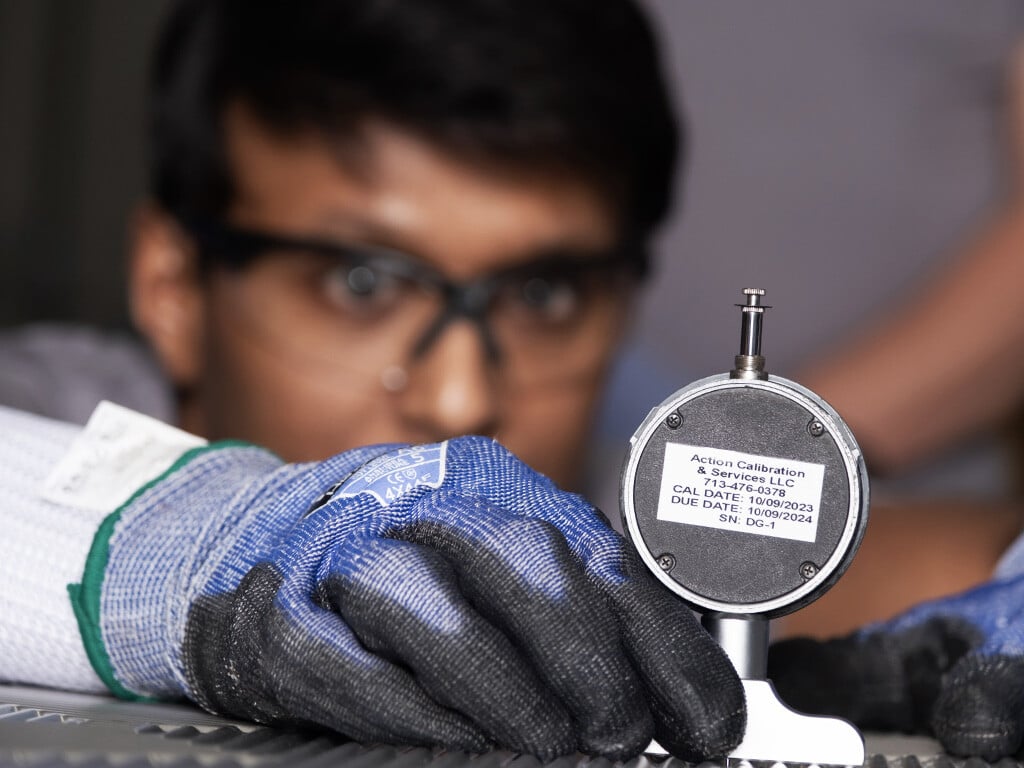

In the semiconductor and microelectronics manufacturing process, industrial etching, uses etching chemical baths to create objects of desired shapes. The etching chemical baths need precise temperature and concentration control, where plate and frame heat exchangers are critical in the acid preparation and controlling the temperature of the etching chemical baths. Tranter’s plate and frame heat exchangers can be manufactured with plates in various high alloys or nickel alloys, capable of handling corrosive chemicals and acids.

Water treatment of ultrapure water (UPW) and process cooling medium is vital in the semiconductor industry to ensure the water’s purity and temperature for the different manufacturing processes. Plate heat exchangers are optimal for precise temperature control of the process cooling medium, helping pants to reduce their total water consumption. Ultrapure water (UPW), mainly used for the manufacturing of computer microchips, need precise temperature control and cleanliness. Tranter’s welded plate heat exchangers in titanium ensure cleanliness and precise temperature control in this process.

Wafers are thin slice of silicone ingots used as semiconductor material used as the substrate in various microelectronics for fabrication of integrated circuits. Following the several microfabrication processes like etching, ion implantation, materials deposition and photolithographic patterning, the microcircuits are diced into wafers using wire saws. The silicone ingots are cut using high temperature wire saws that need coolant/cutting slurry which need to be cooled using plate heat exchangers. Tranter’s gasketed plate heat exchangers offers a compact, highly efficient and reliable design for this cooling application.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Sustainability Energy, heating and cooling Energy, Process industries

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

resource center

Energy, Process industries Marine and shipbuilding Sustainability

Energy, Process industries Marine and shipbuilding Sustainability

Resource center

Still curious?