Protect your engines

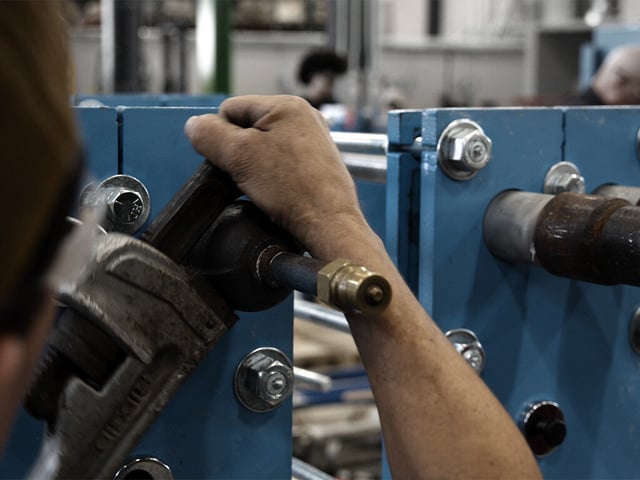

Tranter heat exchangers manage jacket-water and lube-oil cooling circuits in diesel and gas engines, preventing overheating and extending service life under continuous duty.

Genset & cogeneration

When your site depends on on-site power, cooling is mission-critical. Engines run hot, waste heat piles up, and even a small failure can mean lost production, damaged equipment, or penalties under uptime contracts.

With 90+ years of OEM expertise, Tranter heat exchanger solutions are built for the engine cooling and heat recovery you require. We help you extend engine life and turn waste heat into usable energy with compact, service-friendly designs backed by global support.

genset and cogeneration

Tranter heat exchangers manage jacket-water and lube-oil cooling circuits in diesel and gas engines, preventing overheating and extending service life under continuous duty.

Our solutions recover optimal high- and low-grade heat for hot water, steam, or process use, raising total system efficiency and reducing emissions.

Efficient thermal designs reduce fuel demand and chiller load, helping meet both budget and environmental targets.

Compact, modular heat exchanger frames integrate into skids, containers, or retrofit projects without major redesign.

Tranter’s global supply chain gives you access to OEM spares, reconditioning, and field service wherever your plant operates.

Genset and Cogeneration

In diesel and gas-powered generators, Tranter plate heat exchangers cool the engine coolant continuously. By stabilizing jacket-water circuits, they prevent overheating and protect performance in prime, standby, or peak-shaving operation.

Diesel-fired CHP systems generate both electricity and thermal energy. Our solutions provide precise temperature control for coolant, jacket water, and process fluids, ensuring reliable engine operation while capturing waste heat for heating, cooling, or industrial use.

High-temperature waste heat from engines or exhaust can be reused for steam or process applications, while low-grade heat supports space heating, greenhouses, or aquaculture. Tranter exchangers maximize recovery across the temperature range, lowering lifecycle costs and emissions.

Why Tranter

Our heat exchangers are trusted in genset and cogeneration systems worldwide.

90+ years of heat exchanger design and thermal engineering knowledge.

Service centers and supply chain support where and when you need them.

Solutions optimized for jacket water, lube oil, charge-air, and exhaust-heat recovery duties.

Our R&D focuses on the real-world demands of engine-based power: plate geometries that stay efficient with dirty service water, alloys that resist corrosion in challenging environments, and compact frames that simplify skid builds.

Our goal is heat exchangers that run longer between cleanings, cut fuel use, and make your CHP investment more profitable.

With Tranter FullServ®, you get lifecycle support for every brand of heat exchangers. We keep your equipment running, from inspection and reconditioning to emergency on-site service.

Our rapid-response teams and local service centers around the world ensure your exchangers deliver peak performance longer.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Sustainability Energy, heating and cooling Energy, Process industries

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

Resource center

Energy, Process industries Marine and shipbuilding Sustainability

Energy, Process industries Marine and shipbuilding Sustainability

Resource center

Still curious?