On time deliveries

We understand how critical it is for our customers to meet or even surpass project timelines. It's for this reason we are committed to ensuring deliveries are not just on time, but guaranteed to be prompt.

Energy transition

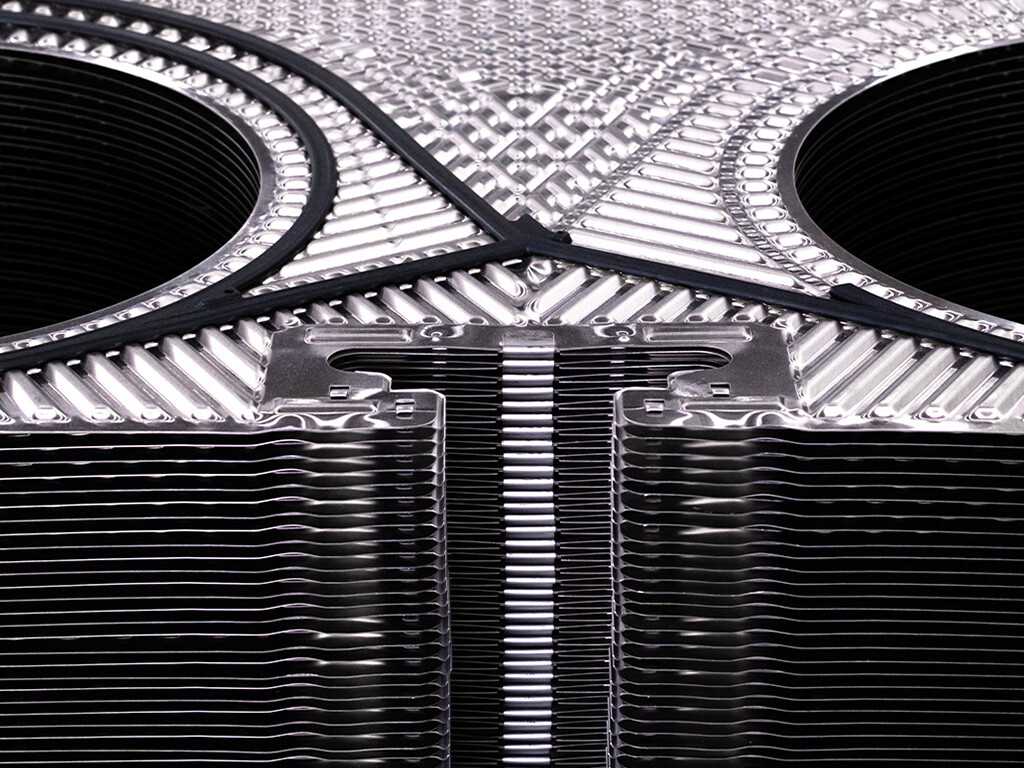

Tranter’s plate heat exchangers play an essential role in renewable energy generation processes, and implementing energy-saving practices to decrease climate change and reduce reliance on fossil fuels. Technologies such as carbon capture and green hydrogen are essential in the fight against climate change, and to reach the NetZero targets, reducing greenhouse gas emissions from industrial process.

Energy transition

We understand how critical it is for our customers to meet or even surpass project timelines. It's for this reason we are committed to ensuring deliveries are not just on time, but guaranteed to be prompt.

Maximize the benefit of our engineering expertise by utilizing our services as extensively as possible. Our team is dedicated to providing top-tier solutions tailored to meet your unique project requirements.

Minimize your project expenses effectively by implementing strategic cost-saving measures. Adopting efficient planning, and ongoing cost analysis can dramatically reduce unnecessary expenditures.

Energy transition

Post combustion CO2 capture involves removing CO2 from gas streams using continuous absorption with regenerable solvents, crucial for reducing greenhouse gas emissions and fighting climate change. Tranter leads in providing heat exchangers for carbon capture, ensuring your plant operates safely and reliably.

Gasketed and welded plate heat exchangers are used in green hydrogen production, in the electrolysis processes, producing hydrogen from water and renewable energy sources like solar, hydro, and offshore wind farms. Tranter's compact and reliable heat exchangers are ideal for skids with limited space or remote installations.

Energy transition

Our plate heat exchanger are important to create efficient energy storage systems, enhancing renewable integration, grid stability, and ecosystem resilience.

Fuel cells transform chemical energy into electrical power via hydrogen-oxygen reactions. Our plate heat exchangers ensure optimal temperature control, thermal, and water management, enhancing performance and reliability.

Power-to-X (P2X) is referring to the conversion of renewable energy to green fuels or chemicals such as green hydrogen, syngas, e-methanol and e-ammonia. Tranter’s gasketed and welded plate heat exchangers are used in various applications in P2X plants to help make the industry more sustainable.

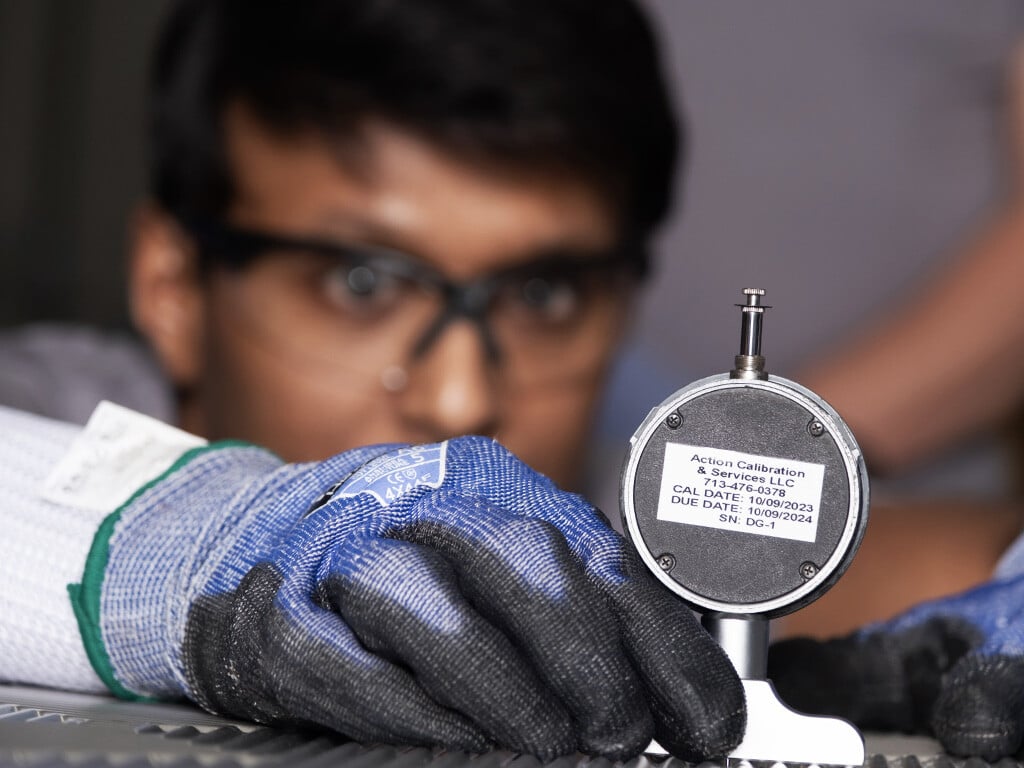

Our comprehensive understanding of heat exchangers goes beyond just maintenance and usage. We offer tailored recommendations and innovative solutions to optimize your system's performance, reduce energy consumption, and extend the lifespan of your equipment. Our goal is to not only enhance your operational efficiency but also to ensure the long-term health and reliability of your heat exchangers. Trust Tranter to provide expert insights that keep your systems running smoothly and cost-effectively.

Resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

resource center

Still curious?