Amazing efficiency in a small footprint

Extreme temperatures, pressures, and special designs that exceed gasket limitations, the compact heat exchangers- Tranter´s Supermax® Shell and plate heat exchangers are your best choice.

Our most reliable product

The best choice for challenging applications.

Astonishing endurance

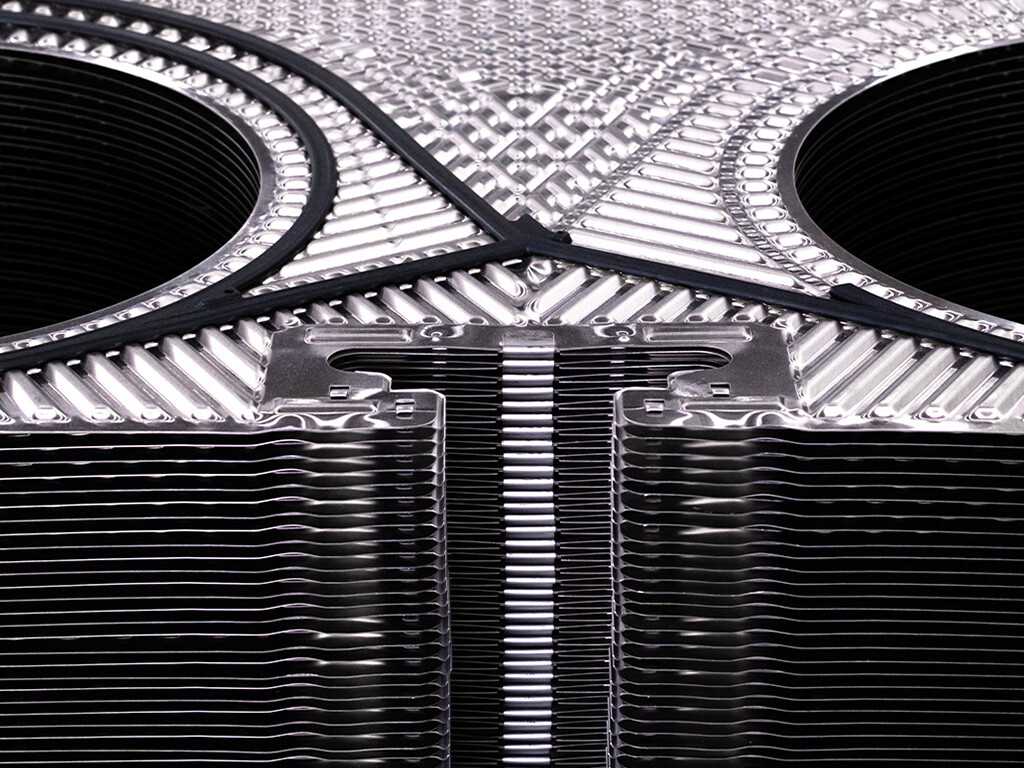

Now you can obtain the thermal efficiency and compactness of gasketed heat exchangers in elevated pressure/high- and low-temperature applications. Tranter´s shell and plate heat exchangers allow you to attain high heat transfer rates under elevated process conditions, in less space and at lower cost than shell and tube exchangers.

Astonishing endurance

For extreme temperatures, pressures, and special designs that exceed gasket limitations, the compact heat exchangers shell and plate heat exchangers are your best choice.

Astonishing endurance

Turbulent flow induced by the corrugated plate patterns produces high heat transfer rates.This high efficiency allows Tranter to design compact exchangers with a 1ºC temperature approach. Another benefit is the small hold-up volume which offers fast start-up times and close following of process changes.

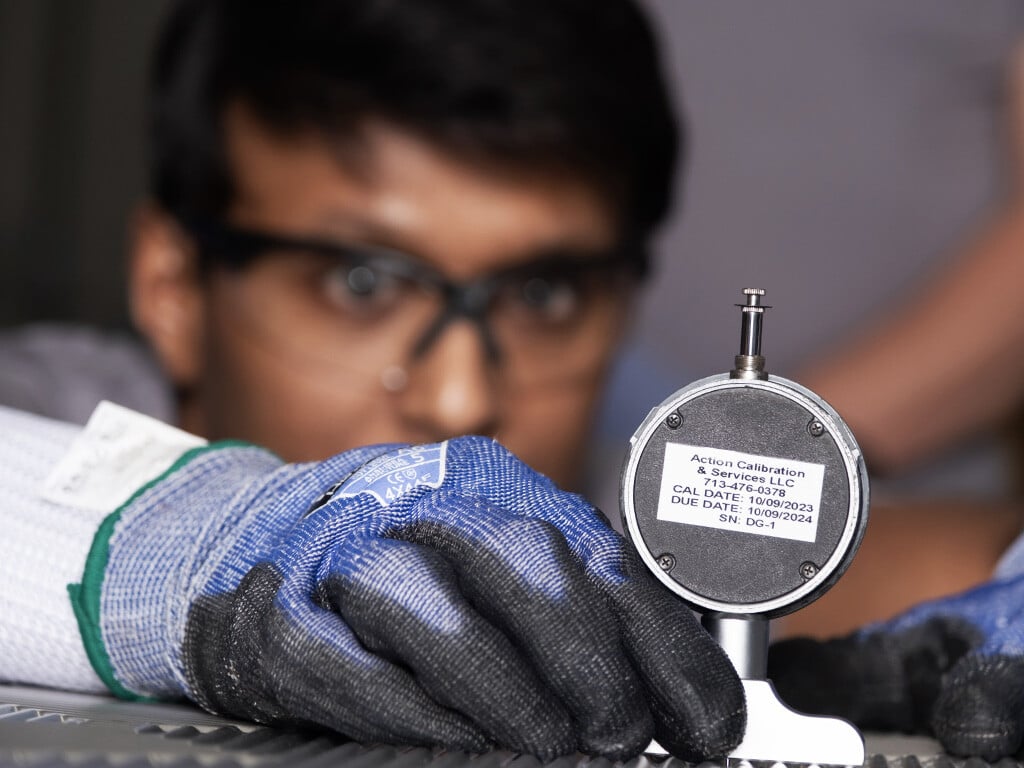

Quality and Reliability

Tranter's shell and plate heat exchangers allow

you to attain high heat transfer rates under elevated process conditions.

Extreme temperatures, pressures, and special designs that exceed gasket limitations, the compact heat exchangers- Tranter´s Supermax® Shell and plate heat exchangers are your best choice.

Which offers fast start-up times and close following of process changes. The advantages of the Supermax® can be applied to challenging applications involving liquids, gases, steam and two-phase mixtures.

The Supermax® shell and plate is particularly suited to applications having a large flow imbalance, allowing higher flow rates on the shell side.

Shell And Plate Heat Exchanger

| Design Code | Plate Material | Shell Material | Design Pressure | Design Temperature | Structure Type |

|---|---|---|---|---|---|

| GB 150 丨ASME丨EN13445丨MOM丨DOSH丨CRN | 316L SS丨C-276丨254 SMO | SA516 Gr.60丨SA516 Gr.70丨304 SS丨304L SS丨316L SS | Welded type: max 130 barg Removable type: max 70 barg | -196 to 540 ℃ | Removable丨Welded |

resource center

Energy, heating and cooling Sustainability

The digitalization mega trend has resulted in exponential growth of data centers. Let’s take a look at how Tranter’s plate and frame heat exchangers can be used to make the datacenters more sustainable.

Energy, Process industries Sustainability

Tranter’s heat exchangers have various applications across many different markets. Let’s take a look at how plate and frame heat exchangers can be used in CO2 capture applications to improve the total economy of the plant.

Energy, Process industries

Tranter’s compact plate heat exchangers are used in various energy intense industrial applications. Let’s take a look at how plate heat exchangers can be used in the production of green hydrogen and in the hydrogen value chain.

Sustainability Energy, heating and cooling Energy, Process industries

Explore our comprehensive brochure to delve deeper into Tranter and discover the wide range of offerings we provide.

Parts and services

With regular service and maintenance you will keep control of your heat exchangers conditions and maintain optimal performance. Learn more from this simplified quick guide.

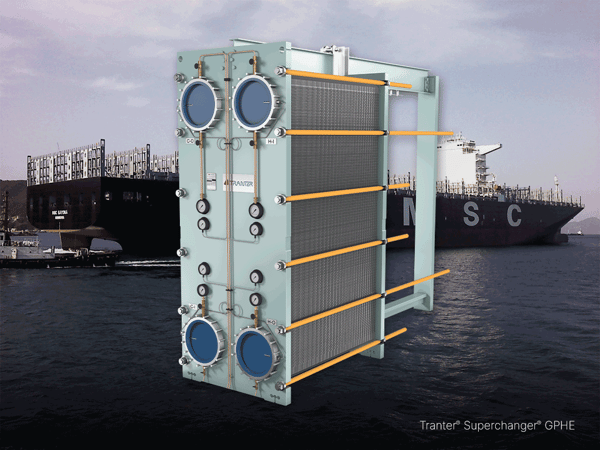

Energy, heating and cooling Energy, Process industries Marine and shipbuilding

For increased durability and energy efficiency. Get some more insights to our welded block heat exchanger with this guide.

Energy, heating and cooling Energy, Process industries Marine and shipbuilding

Now you can obtain the thermal efficiency and compactness of gasketed heat exchangers in elevated pressure/high-and-low temperature applications. Learn more about our shell and plate heat exchanger.

Energy, heating and cooling Energy, Process industries Sustainability

Optimum performance is a promise Tranter has been fulfilling for many decades with the Superchanger® plate and frame heat exchanger.

Energy, heating and cooling

Selecting a heat exchanger is not just about finding an option that fits within your budget. Your choice should strike an optimal balance between cost and performance. Otherwise, you could end up with a unit that’s not designed for its purpose. This mistake can be costly. So, how do you know which exchanger is right for you?

Parts and services

Are you tired of feeling like your heat exchanger is draining your wallet like a car engine left running all night? Our guide walks you through the steps you need to take – from pre-purchase and design to maintenance – to get the most out of your heat exchanger.

Resource center

Energy, Heating and cooling

Marine and shipbuilding

Our comprehensive understanding of heat exchangers goes beyond just maintenance and usage. We offer tailored recommendations and innovative solutions to optimize your system's performance, reduce energy consumption, and extend the lifespan of your equipment. Our goal is to not only enhance your operational efficiency but also to ensure the long-term health and reliability of your heat exchangers. Trust Tranter to provide expert insights that keep your systems running smoothly and cost-effectively.

Are you considering accuiring heat exchangers?