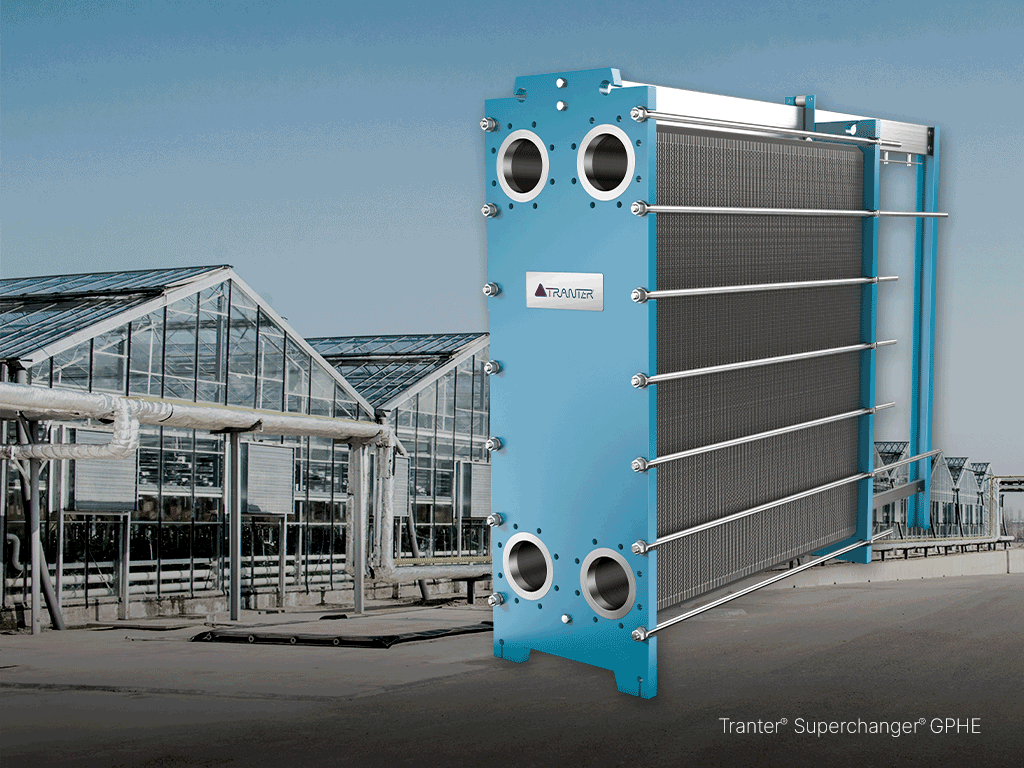

Tranter heat exchangers heating of greenhouses with geothermal energy

Tranter has supplied plate heat exchanger (PHE) equipment to V.B.; a company that specializes in energy supply for greenhouses. The application is a heating system with geothermal hot water as heating source.

The Netherlands has some of the largest greenhouses in the world. Heating is one of the most considerable costs in the operation of greenhouses across the globe. The main problem with heating a greenhouse, as opposed to a building that has solid opaque walls, is the amount of heat lost through the greenhouse covering.

Since the coverings need to allow light to filter into the structure, they conversely cannot insulate very well. The greenhouses in The Netherlands thus have huge energy consumption and to reduce the consumption of fossil energy sources the government supports these geothermal projects to heat greenhouses. VB use geothermal water to heat greenhouses. This geothermal water is coming with 92°Cand 13% NaCl from more than 2000 meter deep in the ground. Eight GXD-325 are being used to separate the geothermal water from the system water and seven GX-265 are used in the heating stations in the greenhouses. All these units are 3-Passunits due the big NTU (>50) and the small LMTD (1°C). The plates in 1.4401 can stand the high Chloride content, because there is absolutely no oxygen in this water.

The successful installation of Tranter plate heat exchangers means that the very small temperature difference between the geothermal hot water and the heating water increase efficiency and reduces costs as well as CO2 emission.

Tranter was chosen as the preferred supplier of heat exchangers because it was recognized that it could deliver high levels of efficiency and adding value when the in- and outlet temperatures are getting so close to each other. The very reliable design and the option to increase the capacity later on, when heat pumps might be installed to reduce the back flow temperature on the heating side, were other good reasons to choose Tranter.

latest customer case

Precision cooling for a digital powerhouse

Energy, Heating and cooling